When it comes to construction, the use of steel beams is essential in the erection of both residential and commercial spaces. Steel beams serve as the skeleton of the building, supporting the weight of the structure. And as steel beams are one of the most common types of structural support used in construction, builders and steel fabricators in Toronto need to know their different types in order to determine which type is best for a specific application. This particular blog will focus on reviewing common types of steel beams based on cross section.

The majority of the names under this classification come from the shape of the beam’s cross section. Below is a more in-depth explanation of each beam type.

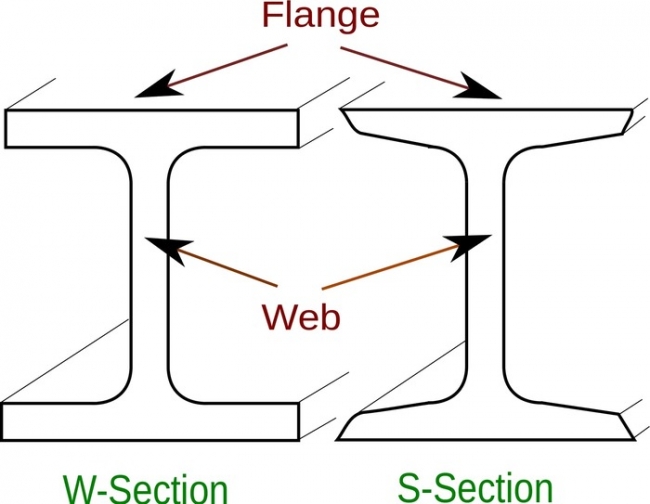

I-beam is a common beam type used by builders and structural steel fabricators in Toronto for its ability to support various loads and withstand a maximum bending load. An I-beam consists of a long vertical section (a "web") and horizontal flanges. These beams are perfect for supporting high-bearing loads.

The structure of H-beams is similar to the one of I-beams. They have wider flanges and thicker central element (the web), which gives them the ability to support larger loads, making them a preferred support structure in the construction of high-rise buildings. H-beams have higher carrying capacity than I-beams, making them a preferred choice in the construction of bridges and other structures requiring reliable horizontal and vertical support.

L-angled beams get their name from the shape of the cross section. They're often used in masonry and repair projects for their ability to lessen weight while offering light weight and strength at the same time.

The name of the T-beam comes from the shape of its cross-section, too. The flange of the T-beam resists compressive forces, whereas the vertical web element is for opposing shear pressure, providing efficient vertical support. T-beams are frequently used by structural steel fabricators in Toronto in structural framing, repairs and in the manufacturing of roof trusses to support heavy loads.

Hollow structural sections (or HSS beams) consist of a circular, square or rectangular beam with a void in the center. They are available in various shapes, sizes, and wall thicknesses. The popularity of HSS beams is growing thanks to their high strength-to-weight ratio, ease of fabrication and their ability to resist torsional load.

Weld Rich & Steel Inc. is a premier steel fabrication shop in Toronto. Started as a mobile welding contractor, we have grown to become one of Toronto’s leading custom metal fabrication shops with an extensive range of metal fabrication services, including structural welding, structural framing and structural steel fabrication.

Boasting a team of highly-skilled and experienced structural steel fabricators in Toronto, structural welders and design technicians, as well as the latest in the metal fabrication and welding technology, we can now handle large-scale custom metal fabrication projects for the construction industry. Call 416-835-5363 or contact us to request a quote.